Precise measurement is essential to achieving peak performance in the field of mechanical systems and engineering one such instrument that is quite important in this field is the vacumetros. The purpose of this article is to examine the use and significance of vacuum cleaner highlighting their advantage application and vital position in a range of industrie.

Understanding Vacumetros:

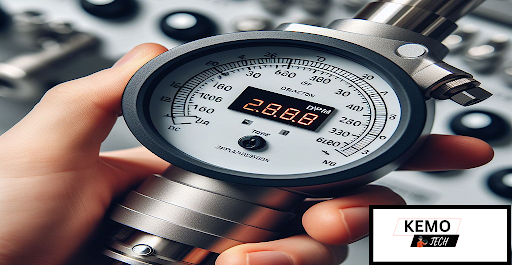

Vacuum and metro the Spanish word for meter are combined to get the term vacumetros vacumetros are essentially instruments meant to gauge and display the amount of vacuum present in a system When we talk about vacuum we mean a space that is empty of matter and vacuum gauge are useful for measuring how empty an environment.

Functionality of Vacumetros:

The basic idea behind vacuum voltmeter operation is the measurement of pressure levels inside a vacuum. These gadget have sensor built in to measure the pressure that the remaining gases in an area are exerting. Vacumetros give a quantitative reading when the pressure in a vacuum drop enabling technician and engineer to evaluate and manage the conditions in a particular system.

Applications in Industries:

Vacumetros are used in many different industrie all of which profit from their special capacity to measure vacuum level. Vacumetros are frequently used in manufacturing processe to monitor and regulate the condition in vacuum chamber used for a variety of purpose such as the manufacturing of aerospace pharmaceutical and semiconductor component.

Vacumetros are essential tool in the automotive industry for determining the vacuum level in a car braking system. This is necessary to make sure that brake booster are operating properly which improves vehicle safety. Vacumetros are also used in scientific research where they help create controlled environment for vacuum condition investigation.

Benefits of Vacumetros:

Precision and Accuracy

Vacumetros offer extremely accurate measurement enabling Technician and Engineer to precisely regulate the vacuum condition inside a system this degree of precision is especially important in field where even minute difference might affect the final product quality.

Process Optimization

Vacumetros help manufacturing processe run more efficiently by allowing the vacuum level to be adjusted. This optimization guarantee consistency in the quality of manufactured good increases efficiency and lower production error.

Safety Assurance

Vascumetros are essential to maintaining vehicle safety in automotive application. These component support dependable and efficient brake performance upholding ideal vacuum level in braking system and improving overall vehicle safety.

Research and Development

Vacumetros let researcher and scientist in research setting create controlled surrounding for studie carried out in vacuum. This is essential for performing experiment in space simulation chamber and investigating a variety of scientific phenomena.

Instrumental in Aerospace

Vacumetros are used by the aerospace industry to evaluate and optimize the performance of space exploration related component. To evaluate the robustnes and performance of material and equipment meant for use in space vacuum condition are replicated.

Conclusion:

Vacumetros are essential instrument in many different industrie because of their capacity to measure and regulate vacuum level. Vacumetros precision and accuracy are used in scientific research automotive application and manufacturing processes all of which enhance technological growth efficiency and safety. Vacumetros continue to play a critical role in guaranteeing the dependability and best possible performance of system that depend on vacuum condition even as technology advances.